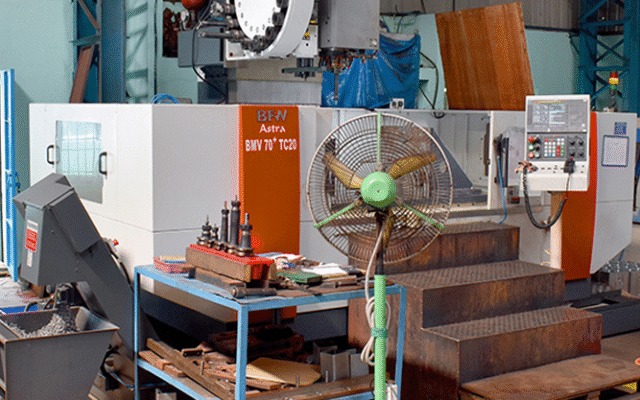

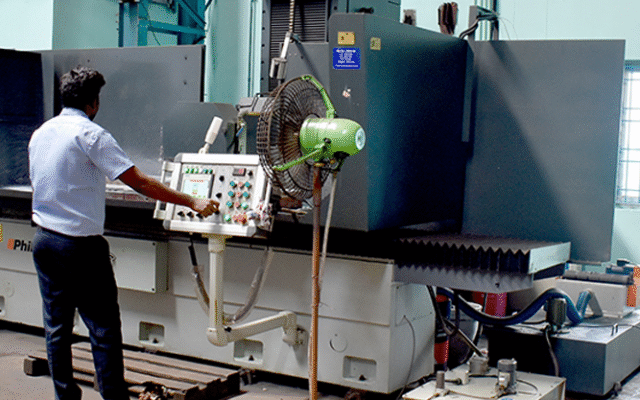

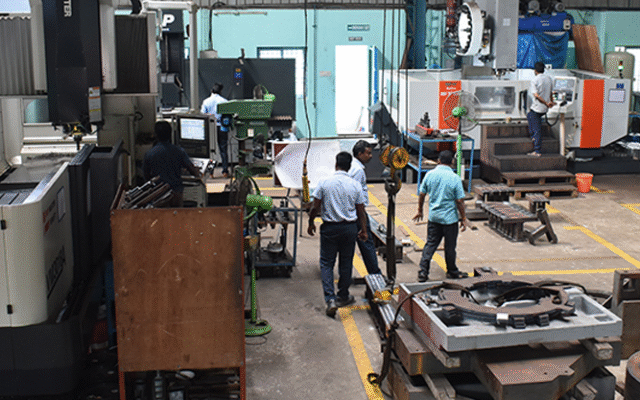

We are pleased to introduce ourselves as a precision engineering unit being in existence since 2000 and being managed by a team of experienced and dedicated engineers and skilled personnel’s. We are involved in the manufacture of highly precision components, accessories etc. Apart from this, we are also involved in Development of import substitution items, Reverse Engineering & Prototype development. We are equipped with the state of art manufacturing and inspection facilities and have put in place established manufacturing and quality control processes in place to ensure production of high quality products to desired standards. We are the registered vendor. Ours is an ISO 9001-2008 certified company. We have invested heavily to implement computerized design technologies and hi-end manufacturing advancements at our factory base. Our machine shop and inspection department are also equipped with modern technology tools and equipment, which is helping us to function proficiently.

What Kind of Parts Are Made by Ganesh Engineering?

Symmetrical – you can have parts with asymmetrical features, but the overall part shape will need to be symmetrical. This has to do with the spinning of the work piece and the stationary position of the part

Cylindrical or round – again, due to the processes’ nature, cylindrical or round parts are what is best suited for CNC turning.

Can be produced from bar or tube stock – the process is working from solid bars of raw material, or tubes. The inner and outer diameter are then shaped by the work piece. If the part is too big or too small, there may not be suitable material for working.