What is a Vertical Machining Centre?

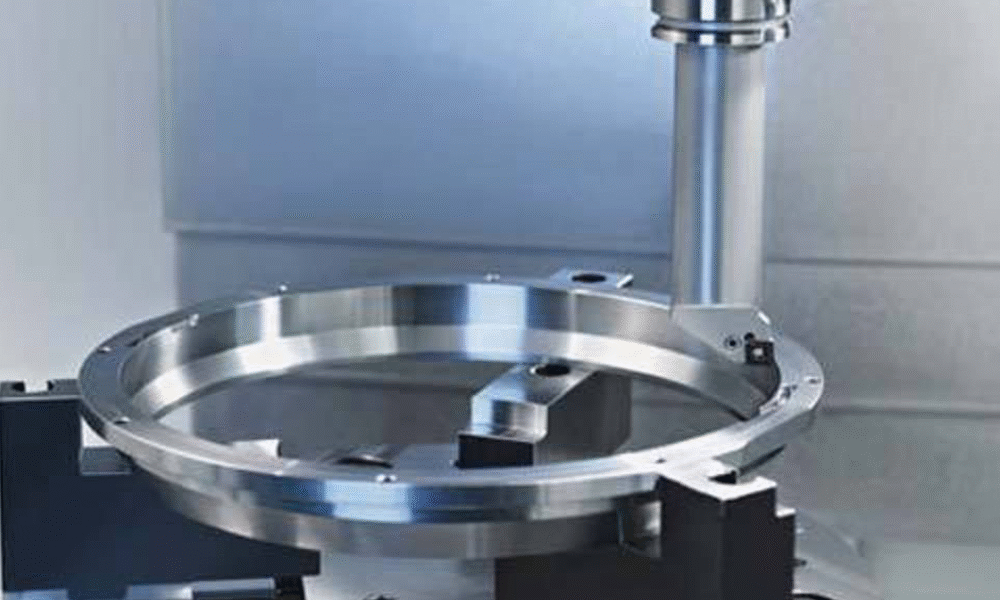

A Vertical Milling Machine is a type of CNC (Computer Numerical Control) system where the spindle axis is vertically aligned. This orientation allows the cutting tool to move vertically over a stationary workpiece for facilitating tasks like drilling, tapping, slotting and shaping.

Unlike horizontal counterparts, VMCs offer better visibility, simplified part loading and efficient chip removal. Their compact footprint, ease of programming and reduced maintenance make them ideal for small-to-medium enterprises aiming to boost production without significant capital investment.

Vertical Milling Machine Applications

VMCs are trusted across industries for their precision, adaptability and ability to handle complex geometries. Their vertical spindle orientation and tight control systems make them ideal for both prototyping and production in sectors where precision is critical.

- Aerospace: Used for machining high-performance components like turbine blades, brackets and structural airframe parts with demanding tolerances and lightweight requirements.

- Automotive: Essential for engine blocks, gearbox housings, cylinder heads and suspension parts, where dimensional accuracy affects vehicle performance and safety.

- Medical Devices: Enable production of orthopaedic implants, dental prosthetics and surgical tools requiring biocompatibility and micron-level precision.

- Tool and Die Making: Used to shape hardened steels for moulds, jigs and forming dies, critical to injection moulding and metal stamping.

Electronics: Precision milling of aluminium and copper for enclosures, connectors, and heat sinks, supporting thermal management in compact devices.

Key Features and Advantages of VMCs

The following features make Vertical Milling Machines indispensable in modern manufacturing environments. Together, these features enable agile, scalable and cost-effective production.

- High-Speed Spindle Performance: Enables faster material removal, superior surface finishes and higher productivity, especially in high-precision applications.

- Advanced CNC Control Systems: Allow seamless execution of complex tool paths, multi-axis movement and batch repeatability with minimal human error.

- Compact Vertical Design: Saves valuable floor space and allows for efficient cell layouts in workshops with space constraints.

- Cost Efficiency: Lower acquisition costs and simplified maintenance compared to horizontal machining centres, without compromising on performance.

- User-Friendly Interfaces: Intuitive programming and controls reduce the dependency on highly trained CNC operators for faster onboarding and setup.

- Flexible Tooling Options: Support a wide variety of tool configurations, making them suitable for both prototyping and production runs.

- Automation Compatibility: Easily integrates with robotic arms, pallet changers and Industry 4.0 systems for smart, unattended machining.