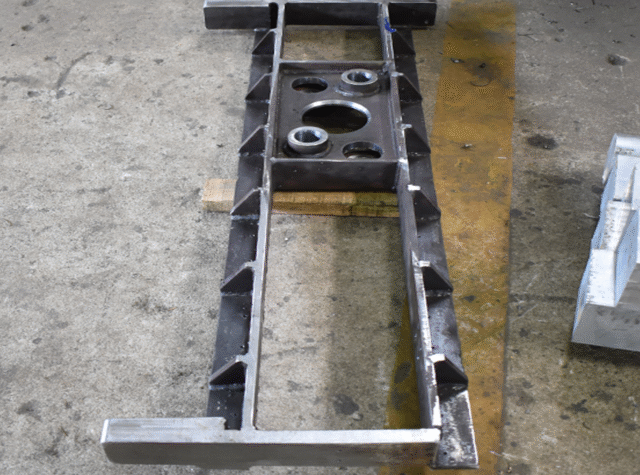

Fabricated Steel Machine Frame

- Processing techniques: CNC, EDM, turning, stamping, hobbing, milling, grinding, drilling, cutting etc

- Surface Treatment : Nickel

- Size: Customized Dimension,tolerance ± 0.01mm

- Material Hardness: 40 – 65 HRC

- Finish: Polishing, painting, anodizing, sandblasting, plating, blackening, electrophoresis.

Fabricating a steel machine frame involves creating the overall structure through welding and joining, followed by using CNC turning operations for precision finishing on specific components like shafts or housings. CNC machining is used for its accuracy in creating high-strength parts

100% Quality Assurance program taken by best-in-class inspection equipment, rigorous QC team and meticulous QC process. Material analysis report and component quality testing report as per customer’s specific requirements.