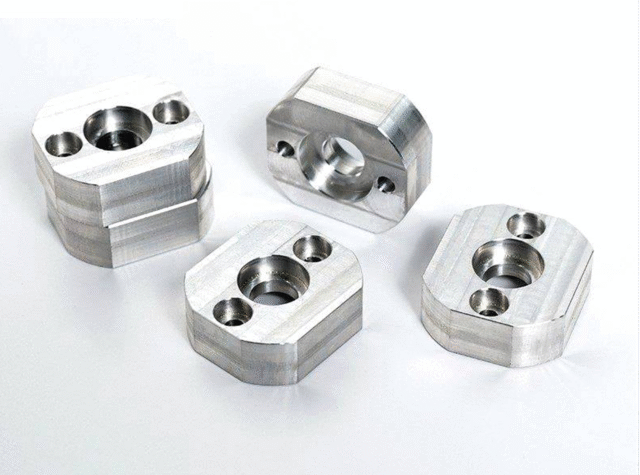

Iron Machinery Part

This is an Iron Machinery Part for RC Car.

- Processing techniques: CNC, EDM, turning, five axis machining, stamping,hobbing, milling, grinding, drilling, tapping, reaming, pulling, cutting, etc

- Size: Customized Dimension,tolerance ± 0.01mm, roughness ≤ Ra0.8μm

- Material: 45 steel,aluminum alloy,stainless steel, plastic,brass

- Finish: Polishing, painting, anodizing, sandblasting, plating, blackening, electrophoresis, QPQ, wire drawing

CNC milling processing is one kind of our most experienced machining processing. It can process the parts with very complex shape and difficult to control size. It even can process the part with complex curves and three- dimension curved surface parts. And it also can reach high precision requirement.

Our CNC milling process produces custom prototypes and end-use production parts as your required. We use 3-axis, 4-axis and 5-axis milling processes to manufacture parts from more than 20 different materials from woods, plastics to metals.

100% Quality Assurance program taken by best-in-class inspection equipment, rigorous QC team and meticulous QC process. Material analysis report and component quality testing report as per customer’s specific requirements.