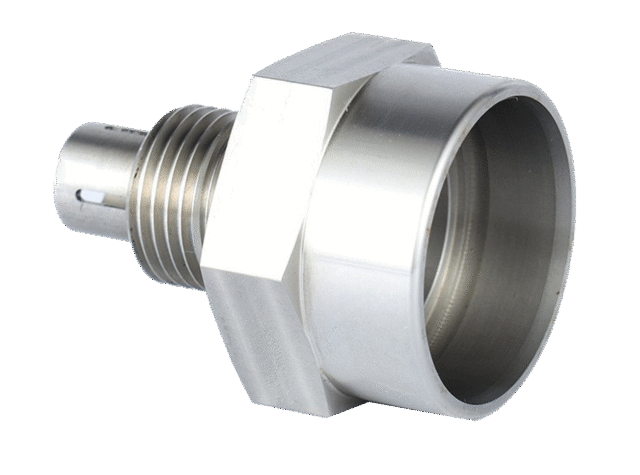

Turning Inserts

- Processing techniques: CNC, EDM, turning, Milling, Grinding, Drilling, cutting etc

- Size: Customized Dimension,tolerance ± 0.01mm, roughness ≤ Ra0.8μm

- Material: 316/304/303/410 stainless steel

- Finish: Polishing, painting, anodizing,sandblasting, plating, blackening, electrophoresis.

- Application fields: Automation equipment,Vehicle, Medical, Aerospace, AI Intelligent, Home appliances

Our processing is one kind of our most experienced machining processing. It can process the parts with very complex shape and difficult to control size. It even can process the part with complex curves and three- dimension curved surface parts. And it also can reach high precision requirement.

100% Quality Assurance program taken by best-in-class inspection equipment, rigorous QC team and meticulous QC process. Material analysis report and component quality testing report as per customer’s specific requirements.